Wet Wipe Production Line: How Does It Work?

2023-03-09 22:00Wet Wipe Production Line: How Does It Work?

Wet wipes, also known as moist towelettes, are pre-moistened disposable wipes that are used for cleaning and sanitizing. They are commonly used in households, hospitals, restaurants, and other industries. Wet wipes can be made from a variety of materials, including cotton, polyester, and other synthetic fibers. In this article, we will discuss how wet wipe production lines work.

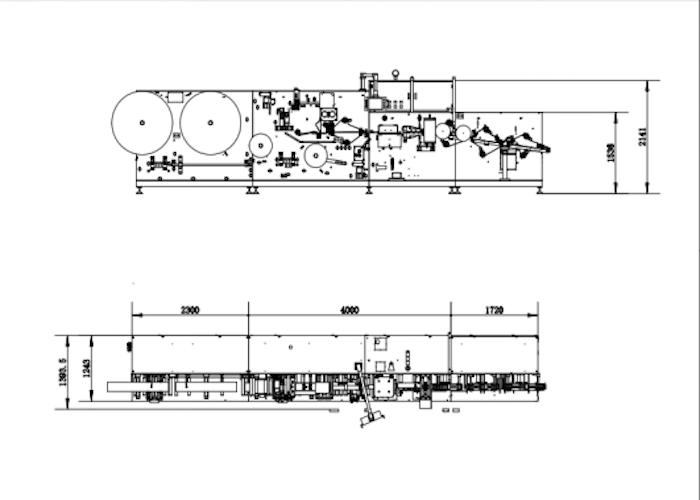

A wet wipe production line is a manufacturing system that produces wet wipes in large quantities. The production line consists of several stages, including raw material preparation, wet wipe making, packaging, and labeling. Let’s take a closer look at each stage.

Raw Material Preparation

The first stage of the wet wipe production line is the preparation of raw materials. The raw materials used to make wet wipes include nonwoven fabric, water, preservatives, and other additives. The nonwoven fabric is usually made from a blend of fibers, such as cotton, polyester, and rayon. The fibers are mixed together and then spun into a web-like material.

Once the nonwoven fabric is prepared, it is cut into the appropriate size for the wet wipes. Then, the fabric is fed into a machine that adds water, preservatives, and other additives. The machine mixes the ingredients together and then cuts the wet wipes into the desired shape and size.

Wet Wipe Making

The next stage of the wet wipe production line is the wet wipe making process. Once the wet wipe solution is prepared, it is fed into a machine that converts the solution into wet wipes. The machine uses a series of rollers to apply pressure to the wet wipe solution, which forces it through the nonwoven fabric.

As the wet wipe solution is forced through the nonwoven fabric, it absorbs the solution and becomes moist. The machine then cuts the moist fabric into individual wet wipes and stacks them into a pile.

Packaging

Once the wet wipes are made, they are ready for packaging. The packaging process involves placing the wet wipes into a container, such as a plastic canister or a resealable pouch. The packaging is designed to keep the wet wipes moist and prevent them from drying out.

The packaging machine fills the container with a certain number of wet wipes and then seals the container. The packaging machine also applies labels and prints the expiration date on the container.

Labeling

The final stage of the wet wipe production line is labeling. The labeling process involves applying labels to the packaging that indicate the brand, product name, ingredients, and other information. The labels are usually made from a durable material, such as vinyl or polyester, and are designed to withstand moisture and wear.

The labeling machine applies the labels to the packaging using a series of rollers and adhesive. The machine also prints barcodes and other information on the labels.

Conclusion

In conclusion, wet wipe production lines are complex manufacturing systems that produce wet wipes in large quantities. The production line consists of several stages, including raw material preparation, wet wipe making, packaging, and labeling. The final product is a pre-moistened disposable wipe that is used for cleaning and sanitizing. Wet wipes are a convenient and effective way to keep surfaces clean and germ-free.