Pre-made bag on wickets baby diaper packaging machine

Why choose GACHN

1.Gachn is a reliable full auto baby diaper bagging machine manufacturer and supplier, leader in designing and manufacturing automated diaper packaging equipment.

2.Gachn Technology has been used to package more than 30 baby diaper brands both in China and internationally.

3.More than 20 years of designing and manufacturing experience in hygienic business.

4.Gachn's baby diaper technology has won the trust of P&G's biggest OEM contractor in China

- GACHN

- CHINA

- 3 MONTHS

- 400 SETS/YERA

- Information

Applications

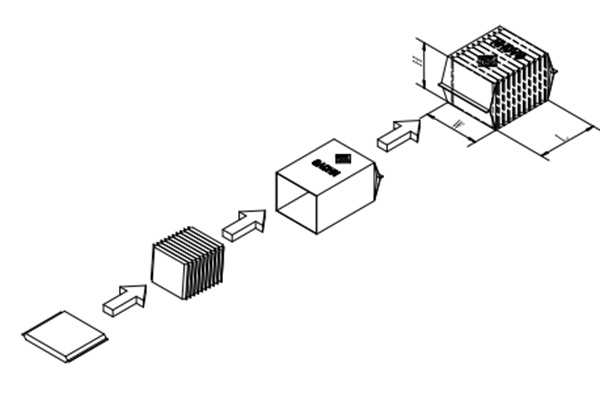

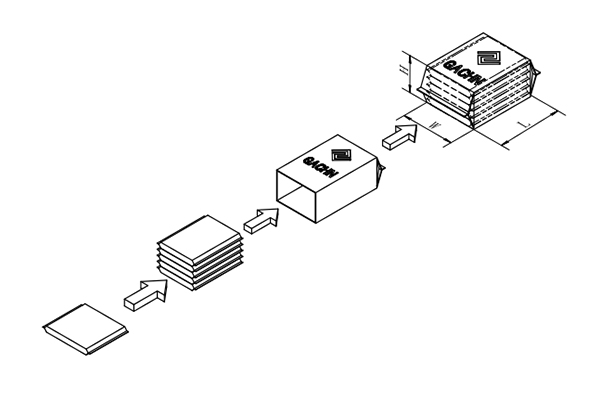

This premade bag packaging machine primarily uses a premade bag packing method that packages the stacked baby diapers into premade bags and then seals the bags. Its whole bag stacking bagging, stable bag moving and opening all improve the artificial bag efficiency by reducing the frequency of manual bag placement.

Packaging Details

The pre-made bag baby diaper packaging machine uses a four pusher head design, which reduces the push head running speed, in turn allowing the equipment to operate more stably.

Whole bag stacking bagging, stable bag moving and opening all improve the artificial bag efficiency by reducing the frequency of manual bag placement.

Sealing, gusset, forming three-axis linkage control, compact packaging, small misplaced angle, nice packaging look.

Well-designed machine structure, ability to quickly dock with the host.

Highly stable angle line structure, angle line deviation ≤5mm.

Accurate sealing line, sealing ling deviation10± 6mm.

The baby diaper pack counting machine can achieve symmetrical sealing, with a symmetric deviationof ≤5mm.

| Packing Speed | Rated Speed | 40 bags/min |

| Stable Speed | 30 bags/min | |

| Packing Method | side gusset bag and bottom gusset bag | |

| Bagging Method | Bag feeding platform | |

| Width of pre-made bag | 180-550mm | |

| Max. pile height for pre-made bag | 550mm | |

| Packing Film | Complex film | |

| Single Package Thickness | 0.04~0.07mm | |

| Packing Dimension | Single row | 350~450(L)mm |

| 180~400(W)mm | ||

| 100~150(H)mm | ||

| Double row | 700~900(L)mm | |

| 130~420(W)mm | ||

| 100~140(H)mm | ||

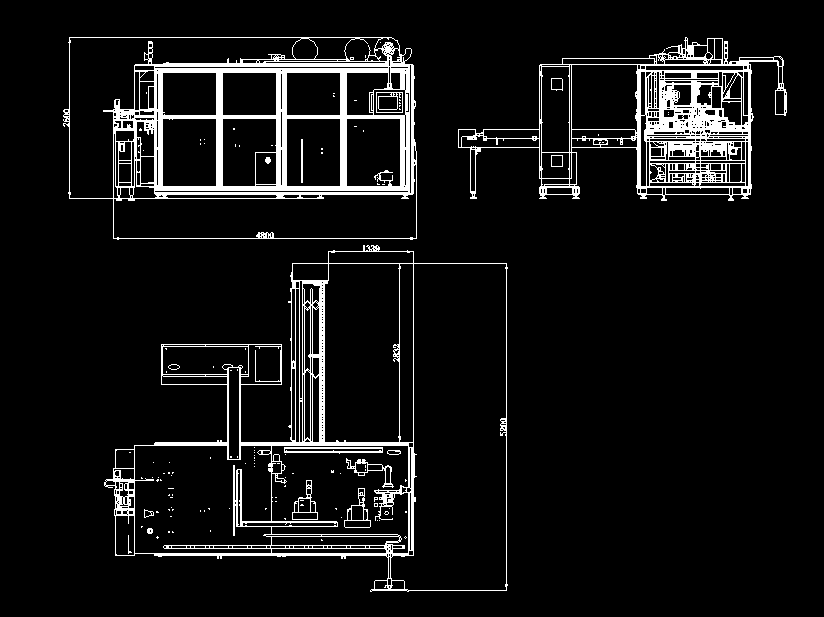

| Machine Dimension | 4.7(L)*4.2(W)*2.8(H)m | |

| Machine Weight | ≈6000kg | |