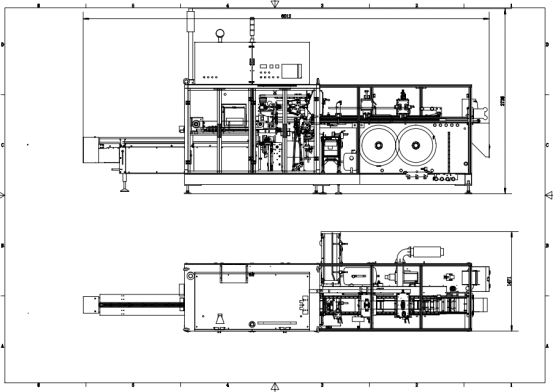

Roll film online bag making wet wipe packaging machine

Why choose GACHN

1.Gachn is a reliable wet wipe packaging machine manufacturer and supplier, leader in designing and manufacturing automated bag packaging equipment.

2.Gachn's wet wipes packaging machine have helped the biggest wipe producer in China capture more than 40% of market share in China.

3.More than 20 years of designing and manufacturing experience in wet wipe machine business.

4.Technology-oriented: GACHN has a technical and R&D team of more than 40 personal

5.we can cooperate with the client to develop new machine design to meet the new products need, such as provide the resource and test stand etc.

- GACHN

- CHINA

- 3 MONTHS

- 400 SETS/YERA

- Information

| Packing Speed | Rated Speed | 50 bags/min | |

| Stable Speed | 40 bags/min | ||

| Packing Dimension | 15~40 pieces/bag | ||

| Single Piece Thickness | ≤60mm | ||

| Packing Film | Composite film | ||

| Single Pad Thickness | <0.1mm | ||

| Folded Non-woven Web | Length | 80~120mm | |

| Width | 80~120mm | ||

| Stacking Height | 20~60mm | ||

| Packing Method | Rolling film tapes, sealing and labeling on line | ||

| Machine Dimension | 5.0(L)*1.5(W)*2.0(H)m | ||

| Machine Weight | ≈2500kg | ||

Features

1. The full servo drive not only ensures a highly accurate package and stability, but also allows for precise control over the speed and positioning of the packaging process. This results in consistent and uniform pouches that meet quality standards.

2. In addition to the full servo drive, the tidiness and clear pouch system further enhance the overall packaging process by preventing wipes from falling, angle folding, or being pressed unevenly. This meticulous attention to detail ensures that the bags are neatly stacked and presentable for consumers.

3. Furthermore, the high sealing quality guarantees that there will be no breakage or weak sealing in any of the packages. With a folding width of ≤1mm and a folding deviation of ≤3mm, each package is sealed with precision and accuracy.

4. Moreover, by automatically bonding with production line, there is no need for manually placing wipes onto it. This not only saves time but also reduces human error in the packaging process.