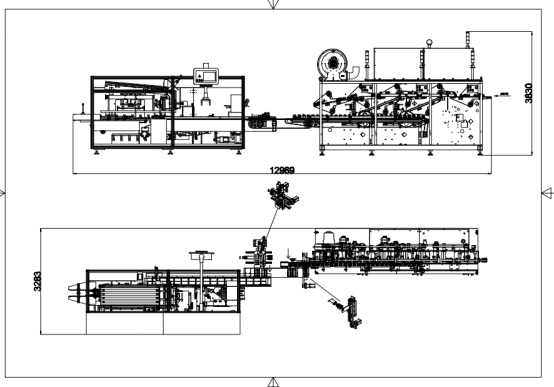

The full servo sanitary napkin counting-cartoning machine

Customization process

1.Clients inform us of their requirements and details of the product, including speed of the main engine, packaging method, measurement of product, measurement of packages, a method for packing the product, number of the products to be packed, coating materials and other information.

2.Gachn will call for a meeting to discuss and draft possible solutions based on client requirements, for example, machine layout, the flow of the process, technical configuration, written information and others.

3.Confirming blueprint and discussing a business contract with the client, for example, date of handover, payment method and more.

4.Gachn starts working on client orders including the installation and debugging of the packing machines after the machine has been produced.

5.Client inspects the machine by the factory before shipping.

- GACHN

- CHINA

- 3 MONTHS

- 400 SETS/YERA

- Information

Why choose GACHN

1.Gachn is a reliable wet wipe packaging machine manufacturer and supplier, leader in designing and manufacturing automated bag packaging equipment.

2.Gachn Technology has been used to package more than 60 sanitary napkin brands both in China and internationally.

3.Gachn's sanitary napkin and wet wipes packaging machine have helped the biggest wipe and sanitary napkin producer in China capture more than 40% of market share in China.

4.More than 20 years of designing and manufacturing experience in hygienic business.

5.In After-sales, our company appoint technical personnel to the buyer’s factory for equipment operation, adjustment, and fault judgment repair training.

6.Technology-oriented: GACHN has a technical and R&D team of more than 40 personal

7. we can cooperate with the client to develop new machine design to meet the new products need, such as provide the resource and test stand etc.

8.Gachn is able to set itself apart from the competition through constant development, a unique targeted design and a well organized service system. These efforts have led to the pursuit of perfect machine and after-sale service throughout the machine’s entire lifecycle.

Technical data

Model: GM-088ZH

Working speed: up to 120bags/min(in relation to the application)

Yield rate: ≥98%

Packing bag type: box

Packing material: paper box

Packing type: laying,upright

Stacking height: ≤90mm

Machine overall size: L8.0m×W2.9m×H2.2m

Installation capacity: about 48KW

Power supply: 3Ph4W(A、B、C、PE), 380V/50Hz

Air supply: 0.6-0.8MPa

Air consumption: ≤300LPM