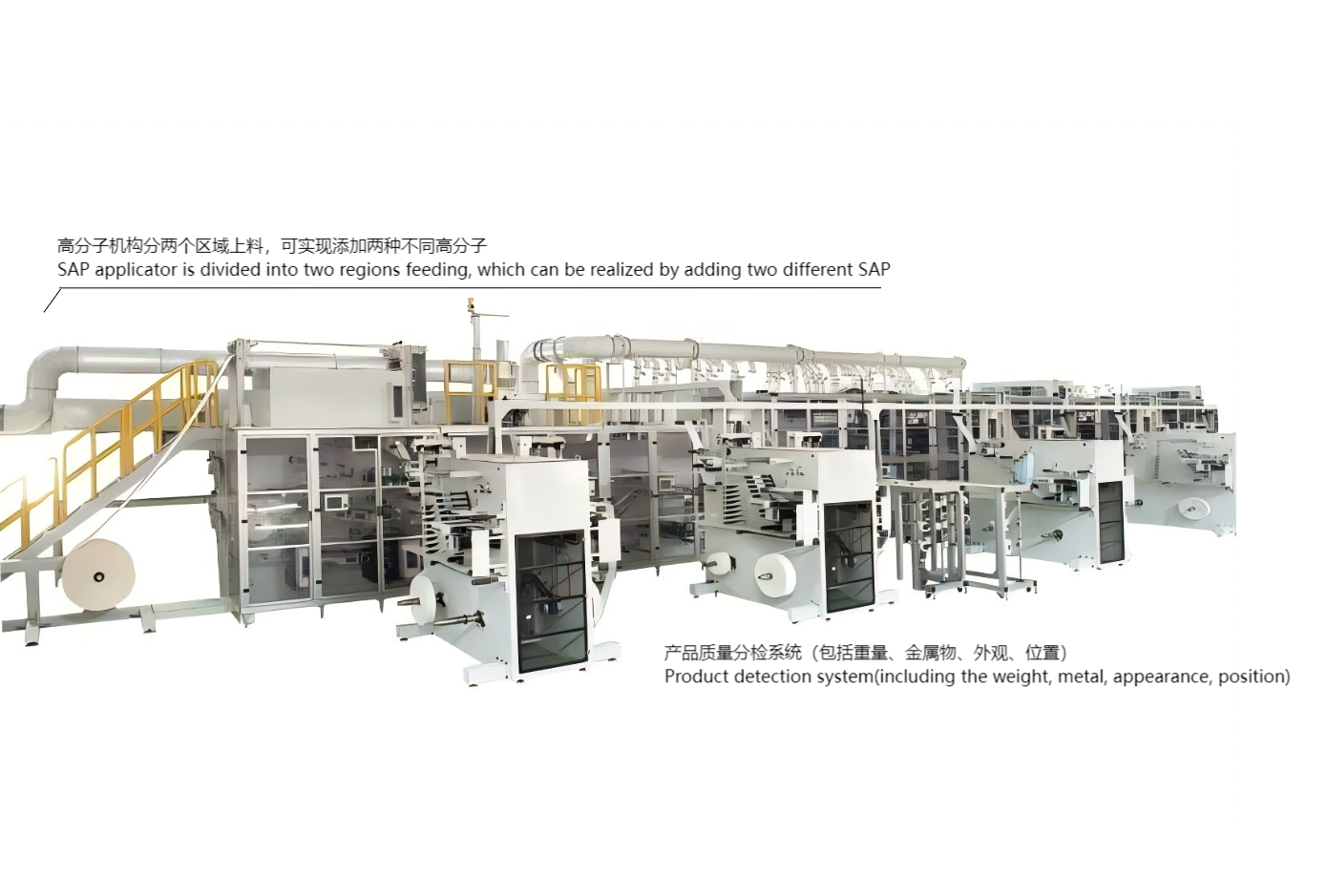

Full Servo Baby Diapers Production Line

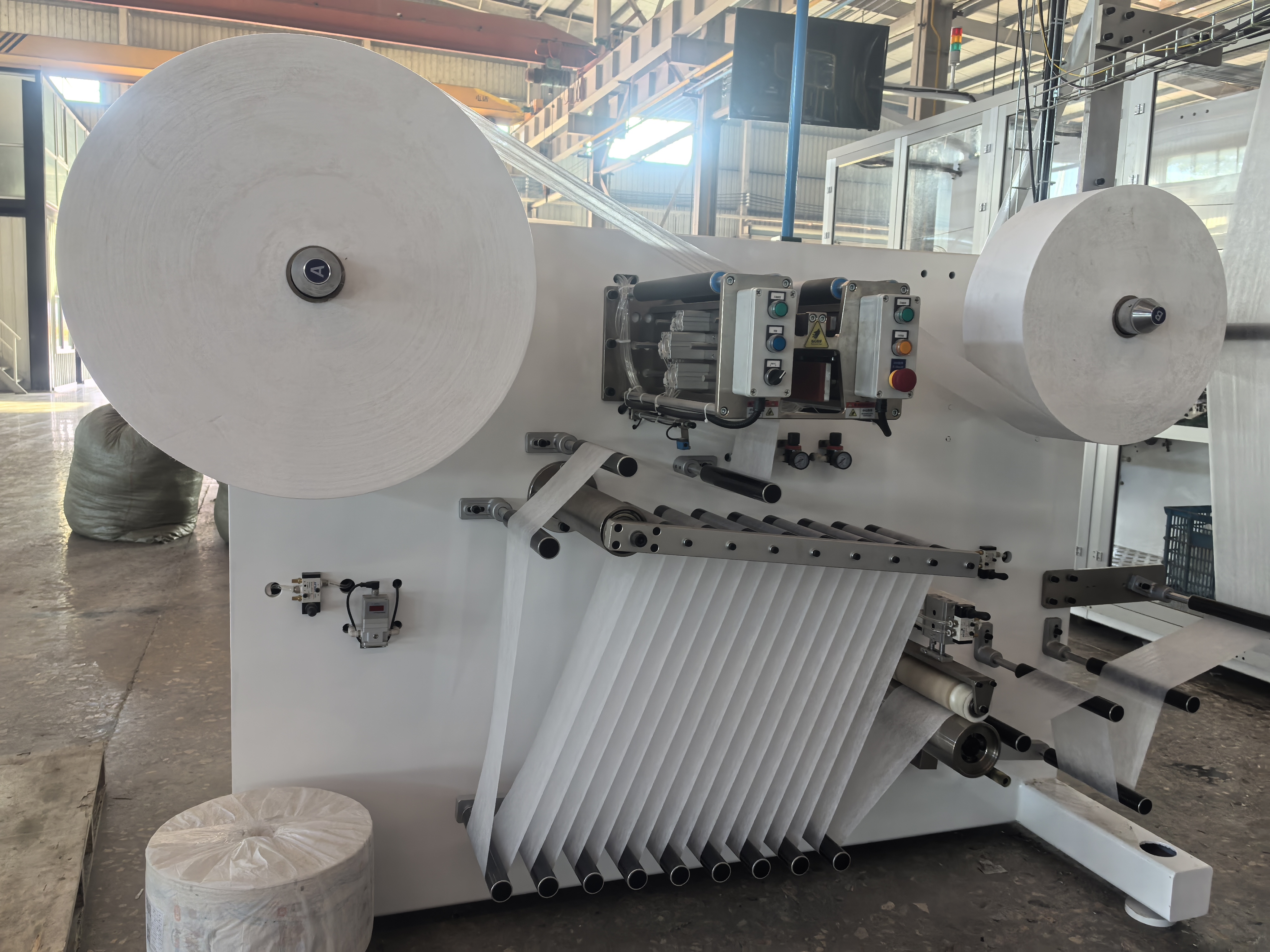

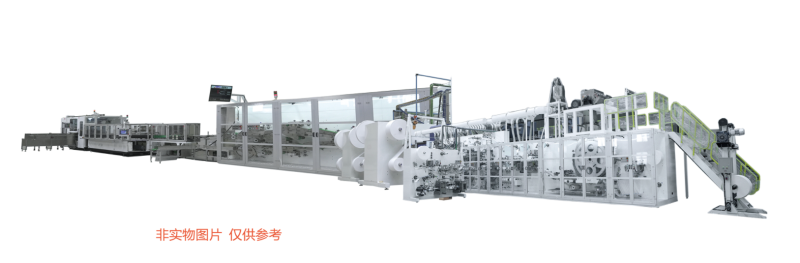

Full servo baby diaper production line is a highly automated production equipment, mainly used for the production of baby diapers, with the characteristics of high efficiency, stability and low reject rate. The full-servo baby diaper production line is suitable for mass production and can automatically refueling without stopping at full speed, which is suitable for modern and efficient production needs.

- Gachn

- China

- Information

Main Technology Data主要技术参数

电源Supply | 3 Phase, 380V, 50Hz |

总功率Power | About 420KW (excluding hot melt applicator and Compressor) |

生产速度Production Speed | 500-700PPM |

外形尺寸Machine size(m) | 35*9*5(L*W*H)(for reference) |

合格率Qualification | ≥97% |

空压Air supply | 0.6-0.8Mpa |

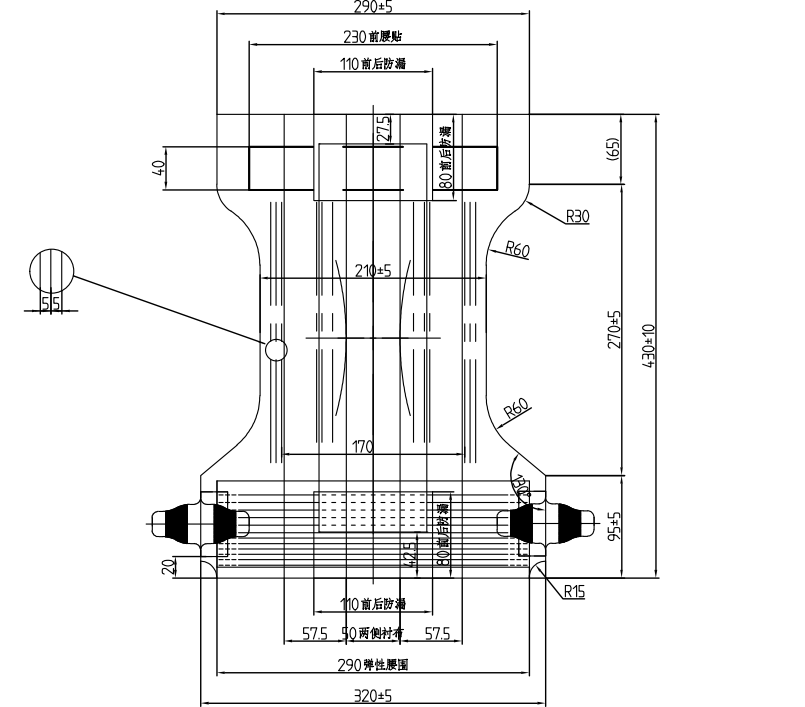

The machine is capable of producing pull-up pants, taped diapers, suitable for the needs of babys in differert ages.

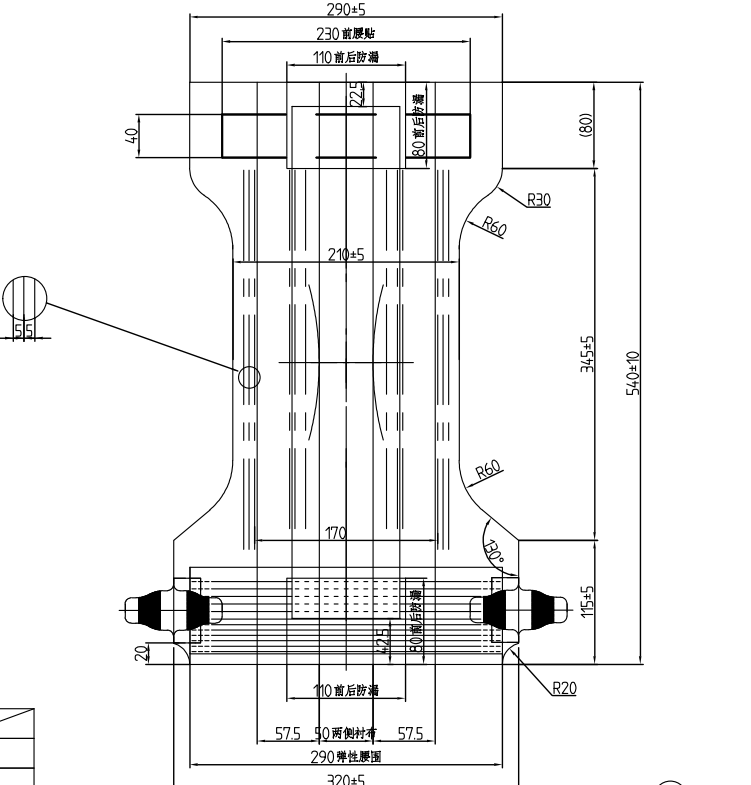

Pull-up pants:

Taped diapers:

Main Functions and Features

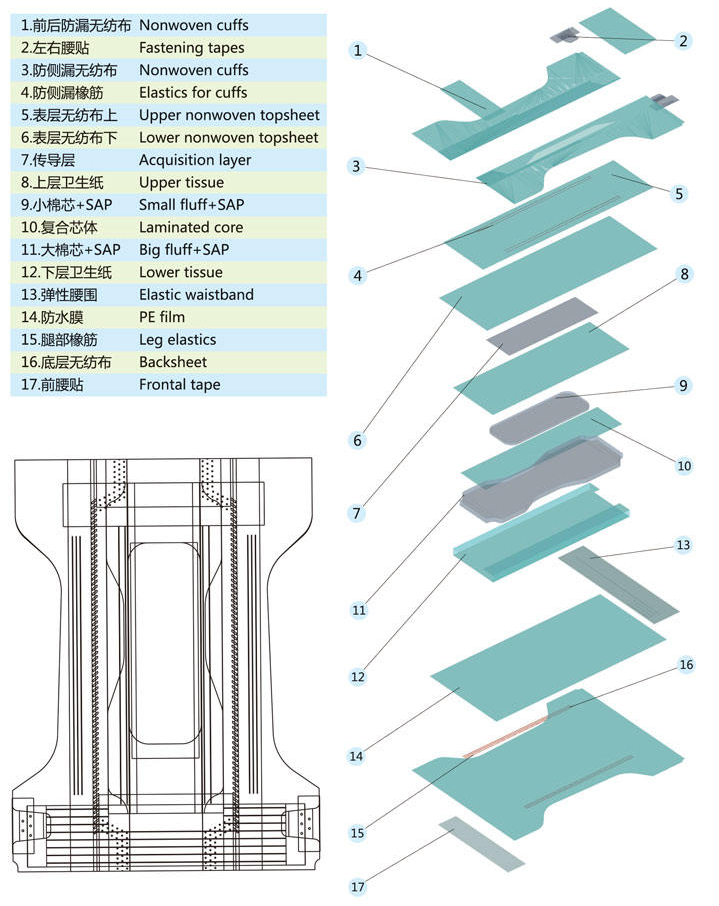

1) Pulp SAP mixing product and laminating core product are compatible

2) High-density ultra-thin fluff core forming system, good absorbability, and low reverse osmosis

3) S cut side tape online making, no waste application

4) One button for size change, quick and less waste

5) High-precision tension control system, active unwinding and auto-splicing system

6) Material auto-splicing end joint limit at 3 meter, and decrease material wastage

7) Material automatic inspect, broken and lost alarm system

8) Material picture ruled position application

9) I-MAS intelligent equipment management and analysis system

Optional features:

3D material online making application

Laminating core online making application

Top sheet 3-pcs laminating ultrasonic process

Packing machine or stacker

Dust collection filter system

SAP Loading parts

Sheet making parts: