Full Servo Sanitary Napkins Production Line

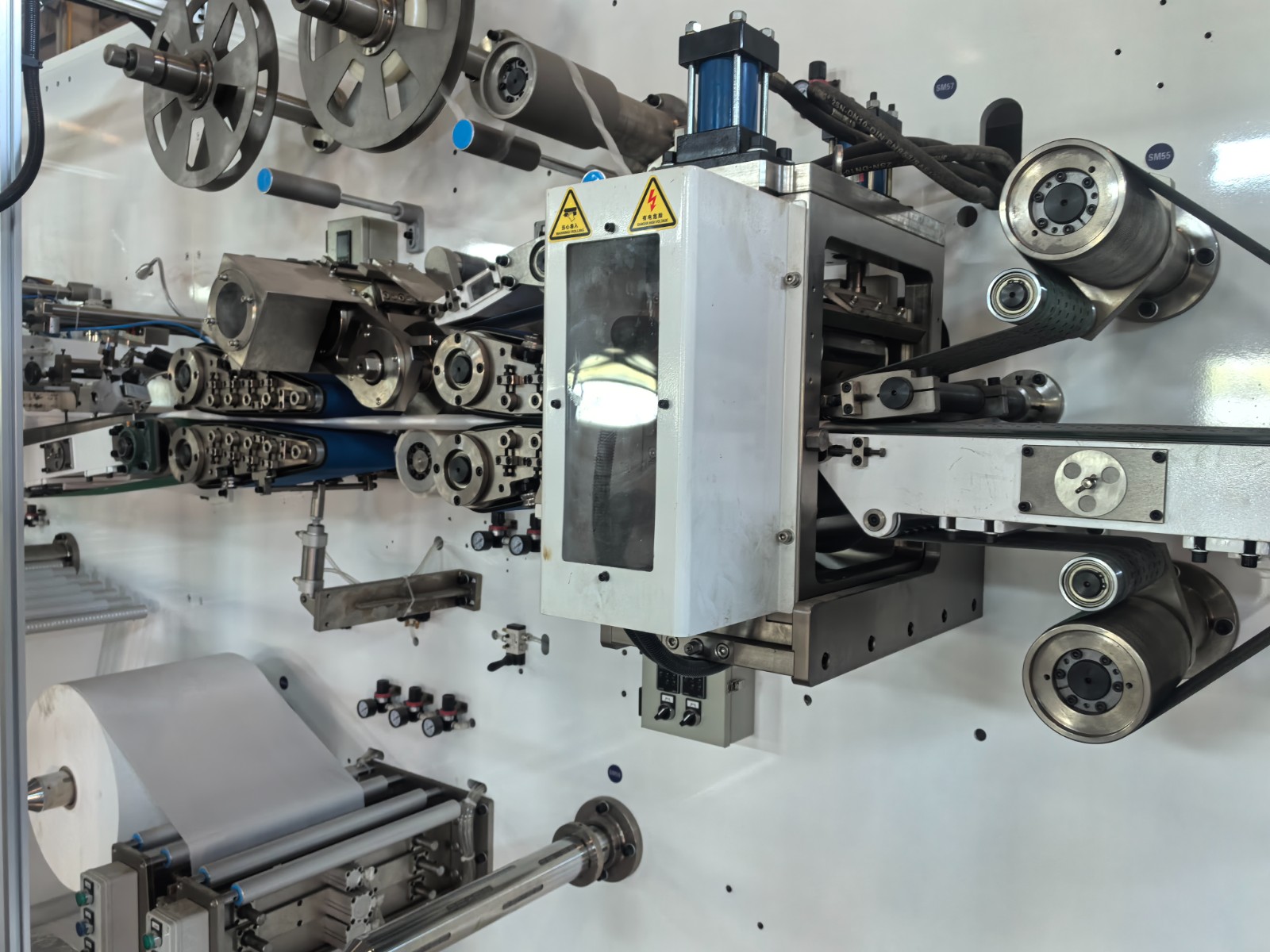

1. Full servo drive system: Full servo sanitary napkin production line adopts full servo drive system, which controls the movement of each component through servo motor to ensure the accurate execution of each process. This system makes the motion transfer between the components more accurate, fast reaction time, low scrap rate.

2. High precision positioning: The production line has a high precision positioning system to ensure that the size and shape of the products are very accurate to meet the needs of high quality production.

3. Efficient production: The design speed can reach 1500 pieces/minute, stable production speed in 1000-1200 pieces/minute, high production efficiency.

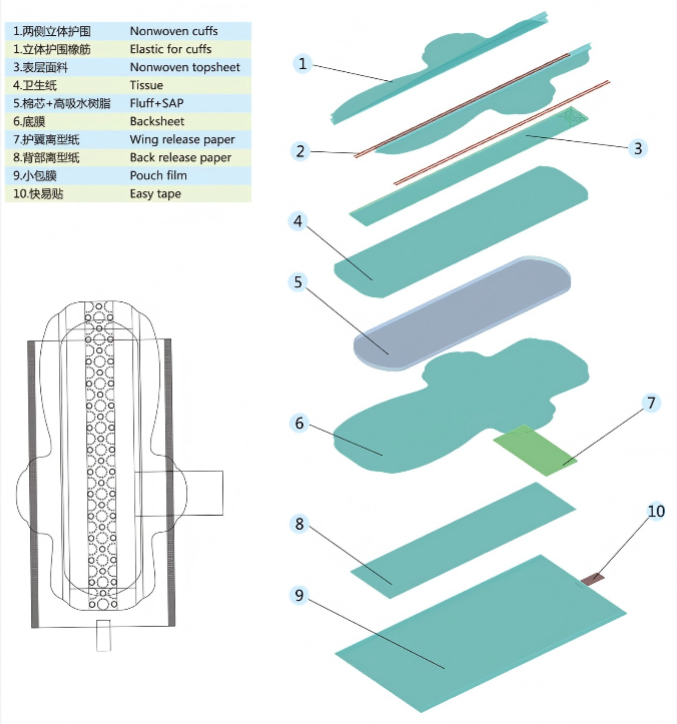

5.Multifunctionality: can produce a variety of types of sanitary napkins, including cotton core, ultra-thin and three pieces and other types of wing pads.

- Gachn

- China

- Information

Main Technology Data主要技术参数

Supply | 3 Phase, 380V, 50Hz |

Power | 180-330KW(excluding hot melt applicator and Compressor) |

Production Speed | 800-1500PPM |

Machine size(m) | 32*8.5*5(L*W*H)(for reference) |

Qualification | ≥97% |

Air supply | 0.6-0.8Mpa |

Machine features:

Capable of producing high quality pads with multiple features, offering overall protection for your health.

1) Pulp SAP mixing product and laminating core product are compatible

2) High-density ultra-thin fluff core forming system, good absorbability

3) Core punching online and top sheet printing rule position function

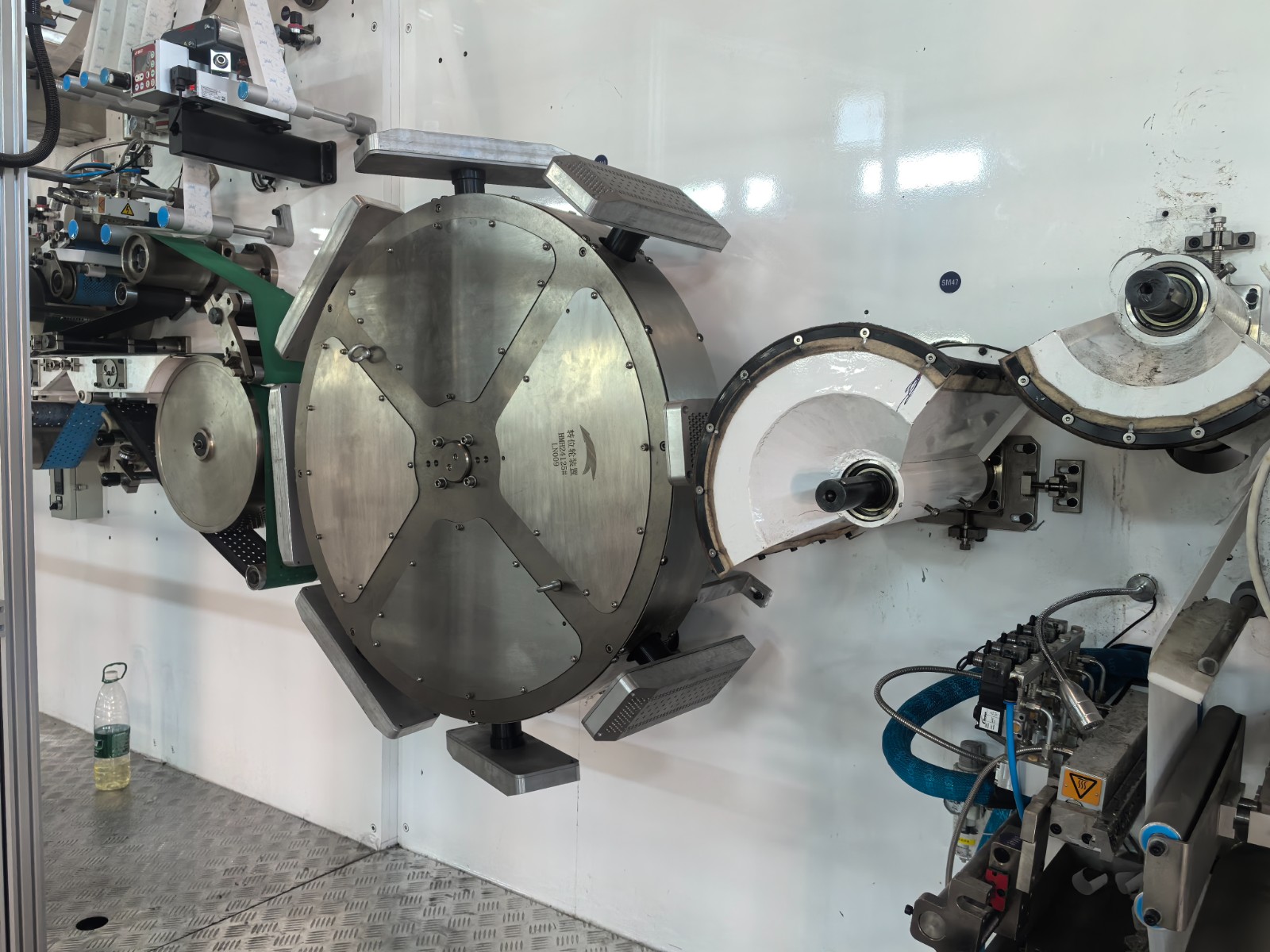

The machine includes main machine, glue applicatos, and can connect to a packing system and other accessory equipments include air compressor, vision detection system and metel detection machine etc.

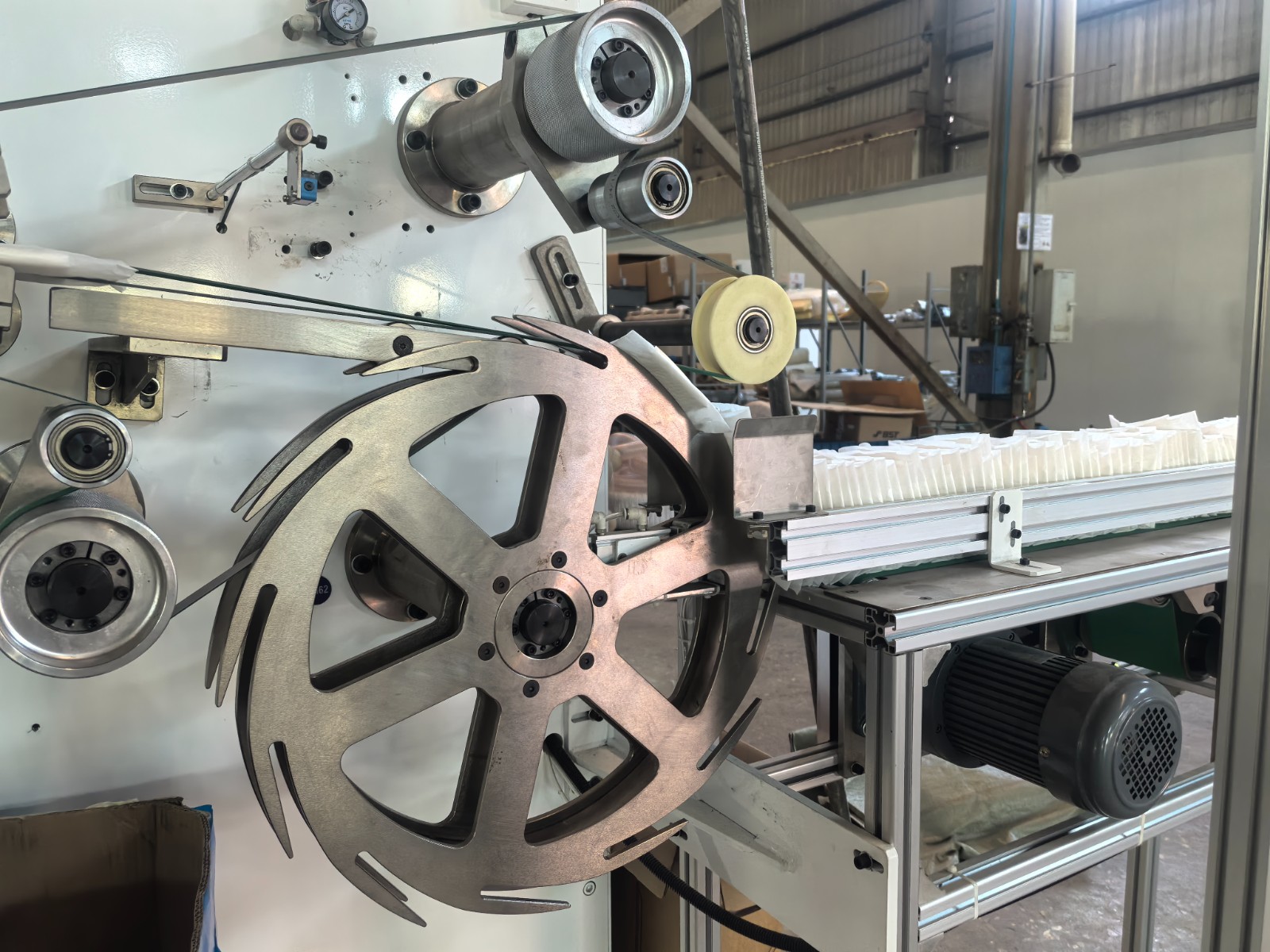

The ability to rotate products in different orientations for the collaboration of packing system.

With web guiding system.

Other features:

1) One button for size change, quick and less waste

2) High-precision tension control system, active unwinding and auto-splicing system

3) Material auto-splicing end joint limit at 3 meter, and decrease material wastage

4) Material automatic inspect, broken and lost alarm system

5) Material picture ruled position application